Micro Thermal Inkjet for Fuel Injection

Inkjet printheads is one of the most successful microfluidic products at this moment . Generally speaking, there are two kinds of inkjet: piezoelectric inkjet (Epson, etc) and thermal bubble jet (HP, Cannon, etc). This project apply thermal inkjet to fuel injection in engines to achieve higher efficiency. One novel drop-on-demand thermal inkjet has been fabricated on a silicon wafer by using surface and bulk micromachining (7-mask photolithography). High temperature materials (silicon nitride, silicon and silicon dioxide) have been used in the device to ensure operation at high temperature.

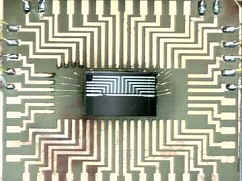

Figure 1: SEM picture of a microinjector array.

Figure 2: Microinjector packaged on a printed circuit board

(PCB)

Figure 3: Tygon tubing connection at the backside of the

PCB

Figure 3: Micrograph of a microinjector (top view) (a) not powered (b) the case of mist ejection.

Figure 4: Diesel fuel droplet ejection from a commercial inkjet printhead (60 mm nozzle). All are at 40 ms after firing but with incremental energy input. (Click to enlarge)

Figure 5: Diesel fuel droplet ejection from our microinjector (30 mm nozzle). All at 20 ms after firing but with incremental energy input. (Click to enlarge)

Selected reference

Y.K. Lee, U.C. Yi, F.G. Tseng, C.J. Kim and C.M. Ho, "Fuel Injection by a Thermal Microinjector," Proceedings of MEMS," ASME International Mechanical Engineering, Nashville, Tennessee, Nov, pp. 419-425. 1999.